Excerpt Forum

Understanding the Excavator Swing Motor: A Comprehensive Guide

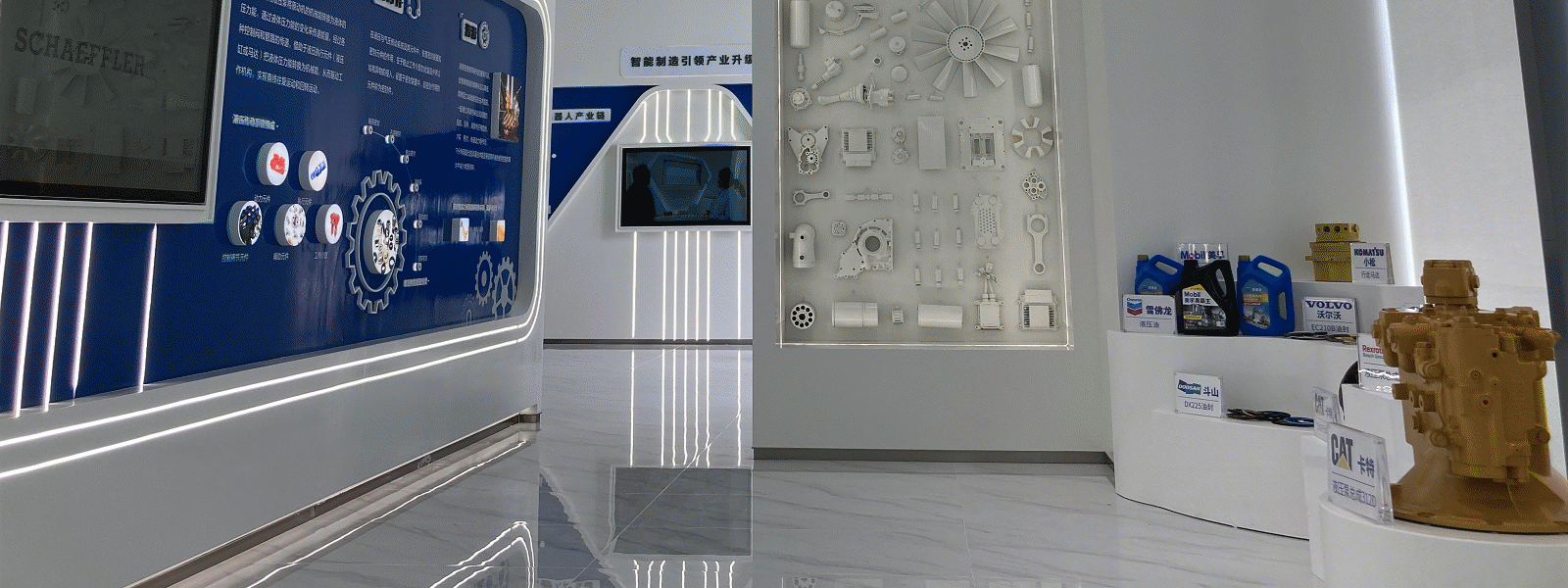

Quote from Guest on January 22, 2024, 2:33 amIn this tutorial, we will delve into the intricacies of the excavator swing motor and its significance in Vermont's construction industry. The excavator swing motor is a vital component that enables the rotation of an excavator's upper structure, allowing for efficient digging and maneuvering capabilities.The Role of Excavator HydraulicsExcavators rely on hydraulic systems to power their various functions, including the swing motion excavator hydraulics.The utilize pressurized fluid to transmit force from one part of the machine to another. This system plays a crucial role in controlling and powering the movement of both small-scale and large-scale excavation projects.The hydraulic pump supplies high-pressure oil flow to drive the swing motor, which converts hydraulic energy into mechanical energy. This conversion allows for smooth and precise rotation of the upper structure, enabling operators to position loads accurately or dig trenches with ease.Furthermore, advanced excavators often feature variable displacement pumps that allow for better control over speed and torque during swinging operations. These innovations enhance operator efficiency while reducing fuel consumption.The Functionality of Excavator Swing MotorThe primary function of an excavator swing motor is to provide rotational power necessary for turning or slewing movements. It consists of a series of gears driven by pressurized oil flow from the hydraulic system. As oil enters different chambers within these gears, it creates pressure imbalances that generate rotational force.This mechanism ensures smooth operation even under heavy loads or challenging terrains commonly encountered in Vermont's rugged landscapes. Additionally, modern excavators incorporate advanced technologies such as planetary gear systems that distribute torque evenly across multiple gears, further enhancing stability during swinging motions.The Importance of Regular MaintenanceProper maintenance of the excavator swing motor is crucial to ensure its longevity and optimal performance. Regular inspections, lubrication, and filter replacements are essential to prevent wear and tear caused by dirt, debris, or inadequate lubrication.In Vermont's construction industry, where excavators often face demanding tasks in harsh environments, routine maintenance becomes even more critical. By adhering to manufacturer guidelines and scheduling regular servicing intervals, operators can minimize downtime due to unexpected breakdowns while maximizing the lifespan of their equipment.ConclusionThe excavator swing motor plays a pivotal role in Vermont's construction industry by enabling efficient rotation of an excavator's upper structure. Understanding the functionality of this component and its integration with hydraulic systems is vital for both operators and technicians alike. Through proper maintenance practices and utilization of advanced technologies, the excavator swing motor continues to contribute significantly towards enhancing productivity in excavation projects across Vermont.

Quote from Guest on February 20, 2024, 6:34 amAfter teaming up with an impressively Best MEP company, I can't help but highlight their exceptional performance. Their precision and promptness truly distinguish them in the industry. Big applause to the Efficient MEP Company for their outstanding work

After teaming up with an impressively Best MEP company, I can't help but highlight their exceptional performance. Their precision and promptness truly distinguish them in the industry. Big applause to the Efficient MEP Company for their outstanding work

Quote from Guest on February 22, 2024, 5:42 amSo you can shake off the societal judgements and concerns about privacy when booking Escort in Goa Service. Indulge into your passionate fantasies and enjoy a night of uninhibited pleasures discreetly.It is a common fantasy for Indian men to meet. A hot Russian girl and enjoy an erotic night with her. But for most, this remains nothing but an illusion.

So you can shake off the societal judgements and concerns about privacy when booking Escort in Goa Service. Indulge into your passionate fantasies and enjoy a night of uninhibited pleasures discreetly.It is a common fantasy for Indian men to meet. A hot Russian girl and enjoy an erotic night with her. But for most, this remains nothing but an illusion.